SEMI testing and certification

Table of contents

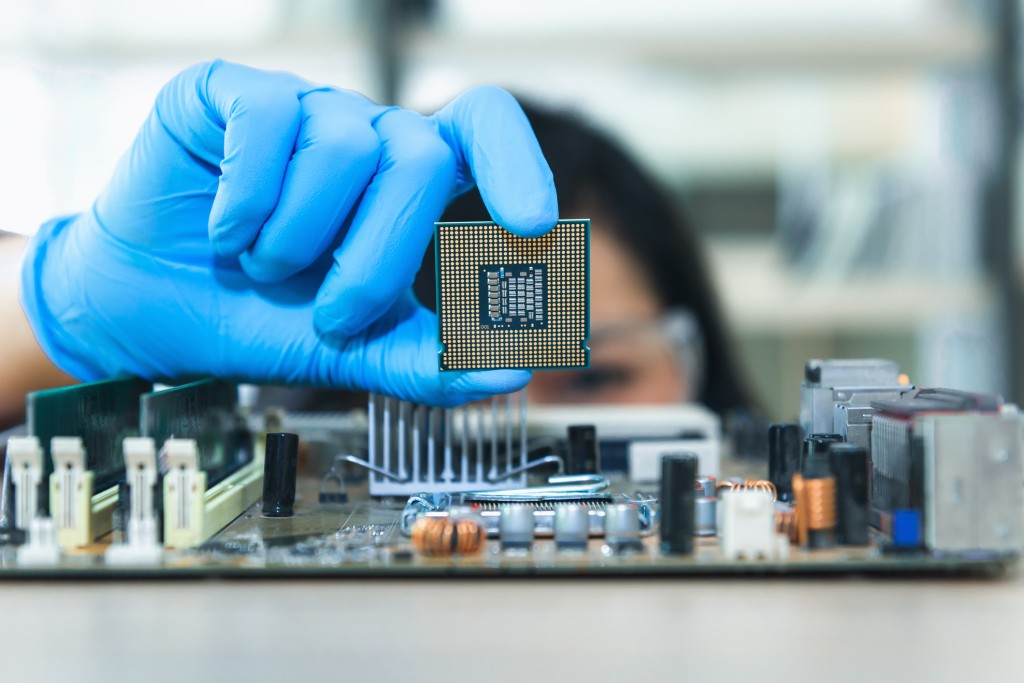

Win customer trust by offering tested semiconductor production

Semiconductors are part of many technologies. They are used, for example, in computers, electric cars and telecommunications. To ensure high standards in terms of safety and sustainability, the industry association SEMI has developed technical standards. Although they are not legally binding, many companies follow them voluntarily, as they are recognized industry standards.

TÜV Rheinland offers testing and certification of the SEMI standards S2 and S8, which document the safety and ergonomics of the machines. We also test and certify the voltage sag immunity of machinery for semiconductor manufacturing in compliance with SEMI F47. This enables you to secure the trust of your customers and open up new markets.

Furthermore, sustainability has become a decisive factor in the semiconductor industry. When purchasing new machinery, for example, many semiconductor manufacturers pay attention to energy efficiency and want reliable proof of its sustainability. You can prove this by having the SEMI S23 standard tested and certified by an internationally recognized partner such as TÜV Rheinland. This is an important competitive benefit for manufacturers of semiconductor production facilities. We are happy to support you right from the development of your machines with our one-stop services.

Note: SEMI stands for “Semiconductor Equipment and Materials”. This is the industry association for the global electronics manufacturing and development supply chain. The SEMI standards also apply to photovoltaic and flat screen manufacturing. If you wish, our experts will gladly assist in all aspects of exporting to the EU, North America, Asia or globally.

Our Services in Semiconductor Production – Testing and Certification according to SEMI

TÜV Rheinland performs the testing and certification of semiconductor manufacturing machines for you in accordance with SEMI standards. As a reliable partner, we support you with assistance right from the development of your product. In addition to the four SEMI standards listed below, there are many other product-specific standards (e.g. for robots, autonomous vehicles, heating systems) and risk-based standards (e.g. electrical safety, chemicals, fire).

- SEMI S2: Environmental, Health, and Safety Guideline for Semiconductor Manufacturing Equipment

- SEMI S8: Safety Guideline for Ergonomics Engineering of Semiconductor Manufacturing Equipment

- SEMI F47: Voltage Sag Immunity Standard

- SEMI S23: Guide for Conservation of Energy, Utilities and Materials Used by Semiconductor Manufacturing Equipment

SEMI S2 and SEMI S8 – Recognized Standards for Safety and Ergonomics

The SEMI S2 and SEMI S8 standards are recognized standards in the semiconductor industry. In many cases, customers make them a condition of their contracts. Complying with SEMI S2 ensures greater safety in the semiconductor industry, which often works with potentially hazardous substances and high temperatures. SEMI S8 ensures that the ergonomics of operating, maintaining and servicing semiconductor manufacturing equipment do not harm the health of the operator. In order to meet SEMI S2 and S8, compliance with American and European requirements and an ergonomic assessment are necessary in most cases.

Our services:

- Support from the design stage – up to SEMI S2/S8 conformance

- Complete SEMI S2/S8 report

SEMI S23 – Sustainable Machines for Improved Market Opportunities

Back in 2005, the industry association SEMI published the first version of SEMI S23. The guideline defines comprehensive requirements for the sustainability of semiconductor production machines. It focuses on the economical use of energy, operating resources and materials used in semiconductor production systems. While initially little attention was paid to the standard, it is now highly relevant for the industry. In 2021, a new version of SEMI S23 was published, which reflects the current state of the art.

Basically, SEMI S23 deals with two aspects.

- Measurement of resource and energy consumption: SEMI S23 provides guidance on how resource and energy consumption can be measured on real machines. Our experts carry out measurements of consumption values on the machine in various operating modes such as production, idle or sleep mode. Relevant variables are electrical consumption, exhaust air, vacuum, nitrogen, cooling media and others. Energy and power equivalents are then calculated using specified conversion factors. Finally, we determine an annual performance indicator from this. This is then used as a benchmark for further developments or even for systems from different manufacturers.

- Reduction of resource and energy consumption: In addition, SEMI S23 defines specifications for a quality system with which manufacturers can reduce resource and energy consumption. For this purpose, consumption should be regularly monitored and reduced if there are new developments.

Our services:

TÜV Rheinland will be happy to support you in determining and objectively evaluating the consumption values and key figures for your equipment. On this basis, you can reduce the values in the future. Moreover, the key figures and compliance with well-defined sustainability standards in accordance with SEMI S23 are an important decision criterion for your customers when purchasing new machines.

SEMI F47 – Voltage Sag Immunity Testing for Reliable Production

Modern semiconductor manufacturing tools can be sensitive to disturbances on the AC power mains. Possible consequences: Production interruptions, problems with sensitive equipment and downtimes. To prevent these occurrences, international manufacturers of semiconductors place great importance on the resistance of the machines. This is why they often require compliance with SEMI F47.

By fulfilling the standard, manufacturers of production machines can ensure voltage sag immunity. The industry standard defines the voltage dip that an industrial machine must tolerate, thereby enabling objective testing of immunity.

Our services:

As one of the few service providers in Europe, we offer a testing for machines with large current consumption – not only in our laboratories, but also as “on-site testing”. The test equipment (IPC-480V-200A) supports SEMI F47, IEC 61000-4-11 and IEC 61000-4-34 testing for 1 or 3 phases at 100–480 VAC, 50 or 60 Hz and up to 200 A load current per phase. Our “on-site testing” saves you time and allows you to have machines tested that cannot be transported to a laboratory.

The standard IEC 61000-6-2:2016 (EN IEC 61000-6-2:2019) includes voltage dips and interruption test according to IEC 61000-4-34 (more than 16 A per phase).

Further Services in the Semiconductor Sector

- Researching local or country-specific requirements in the U.S. or other locations

- Chemical and fire protection evaluations

Your Benefits at a Glance

- Your partner right from the beginning: TÜV Rheinland supports you in the testing and certification of your machines. If required, we can also support you during the development of your production facility. Thus, you can avoid problems right from the start.

- Saving of time and money: Thanks to our continuous support from the development phase up to certification, you can effectively manage processes to save time and money.

- Quality assurance: You demonstrate high quality standards to your customers through our independent and reliable inspections.

- Decreased risk of liability: You decrease your risk of liability with documented safety standards.

- Competitive edge: You gain a competitive edge through a neutral mark of approval. This allows you to quickly show that your production machines are the perfect choice for the semiconductor industry.

- International market access: Certification simplifies access to foreign markets. We will be happy to advise you on exporting your production facilities. Here we can draw on a large international network of TÜV Rheinland locations.

- Excellent reputation of TÜV Rheinland: With a certification from TÜV Rheinland, you benefit not only from reliable quality assurance, but also from our excellent reputation. We are known internationally in the industry as a trustworthy partner. Many companies rely on us as their exclusive testing and certification provider.

- Reliable certifications: We have many years of experience in certifying according to SEMI standards, so you can always rely on our expertise.

Contact