Testing of Industrial Machinery

Optimize the Operational Safety and Efficiency of Your Industrial Machinery

Reliability and safety are the most important requirements for industrial machinery to ensure smooth manufacturing processes. With our comprehensive service portfolio for industrial machinery, you create the best conditions for the conformity and safe operation of your equipment in accordance with national and international regulations. As part of the machine assessment, risk potentials are identified early on and downtime rates are reduced. The internationally recognized reports and approvals provided by our independent experts enable you to demonstrate your commitment to a safe working environment and to high quality standards.

This firm commitment to safety, quality and sustainability gives you an enormous advantage over your competitors. Contact our experts to discuss your specific requirements.

Experience the Benefits of an Expert Machinery Inspection

Benefit from the advantages of an independent certificate upon successfully completing the test. With a globally recognized certification, you document compliance with safety standards, reduce your liability risk, and offer your customers a valuable tool for decision-making when selecting a product.

By testing your industrial machinery, you can internally identify mistakes during development at an early stage and avoid risks, costs, and malfunctions.

We conduct our machinery assessment according to international norms and standards – from the EU Machinery Directive 2006/42/EC for the European Economic Area to the OSHA Directive 29 CFR 1910 for the USA. We keep track of the ever-changing safety regulations for new, operating, and modified machinery at the local and the global level and ensure the conformity of your machinery.

Our Services for Testing and Evaluating Industrial Machinery

Our experts reliably test and evaluate your industrial machinery. Thus, you can be sure that your machines meet highest quality and safety standards. We support you with the following services:

- Ensuring conformity with EU Machinery Directive 2006/42/EC and with Machinery Regulation (EU) 2023/1230

- Services for machines with increased risk potential

- Consumption measurement for industrial machinery

- Customized solutions for improved machine safety

- Machine testing for international markets and Market Access Services for easier access to new markets abroad

- Services to cyber security

Conformity with the EU Machinery Directive 2006/42/EC

Our machinery assessments are based on EU directives and standards such as the following, and include:

- EC type examinations for machinery according to Annex IV of the European Machinery Directive as a “Notified Body”

- Conformity assessment for products within the scope of Machinery Directive

Technical testing in accordance with the German Ordinance on Industrial Safety and Health, including the following details:

- Quick check for safe operation including documentation review

- Comprehensive analysis with consideration of all risk areas (explosion, cyber security, pressure, etc.)

- State-of-the-art safety analysis as requested by the customer

Conformity with the Machinery Regulation EU 2023/1230

The European Machinery Regulation was published on June 14, 2023 and will replace the current Machinery Directive 2006/42/EC from January 20, 2027. Starting from this date, the CE marking of machinery or assessment of partly completed machinery is only possible according to the Machinery Regulation EU 2023/1230. The Machinery Regulation specifies a 42-month transition period. All machinery placed on the market or put into service before January 20, 2027 must still be CE-marked in accordance with the Machinery Directive 2006/42/EC.

Manufacturers of industrial machinery should prepare for the new requirements in advance. Take advantage of the transition period to adapt your machines to the Machinery Regulation EU 2023/1230. TÜV Rheinland will be happy to test your current machines in accordance with the essential health and safety requirements of Annex III. Or have Annex III of the Machinery Regulation tested as an option for new machine developments.

Testing of Digitalization in Accordance with EU 2023/1230

While about 90 percent of the Machinery Regulation EU 2023/1230 is in line with the Machinery Directive 2006/42/EC, the remaining ten percent of the regulation focuses on digitalization and connectivity. This covers aspects of artificial intelligence (AI) as well as cyber security and the connection of devices to the internet (IoT). In other words, the regulation is adapting to the current state of technology. For manufacturers, this means additional processes that include thorough testing of the machines.

This is where a reliable partner like TÜV Rheinland is needed, because we are already dealing with the new requirements. If you as a manufacturer want to launch your machine in 2027, you need a service provider able to check the listed test standards before 2027 – like TÜV Rheinland.

We will be happy to provide you with advice and assistance in checking the documents submitted for cyber security for plausibility. If there are any irregularities or if the documents are incomplete or inconclusive, our experts will examine them in detail and help you with improvements.

Our Services for Machines

The operation of machines with a considerable risk potential necessitates increased safety requirements.

We provide you with a wide range of services:

- Safety assessment of work equipment (in accordance with the German Ordinance on Industrial Safety and Health, international regulations, the requirements of statutory accident insurance companies and the requests of the operator)

- Preparation of safety analyses on the current state of technology & assessment of machinery in compliance with the current state of technology

- Coordination of the results with the client and collective determination of any measures

Consumption Measurement for Industrial Machines

For many of our customers, the energy consumption of an industrial machine is an important factor when making a purchase decision. This is because companies are increasingly focusing on sustainability and the economic benefits of an energy-efficient machine. In the future, the energy consumption of industrial machines will therefore become even more relevant when deciding whether to buy a machine.

However, the energy consumption is not just information you can pass on to customers. Knowing the consumption is also important for you as a manufacturer of industrial machinery. This allows you to modify the design of your machines to minimize energy consumption.

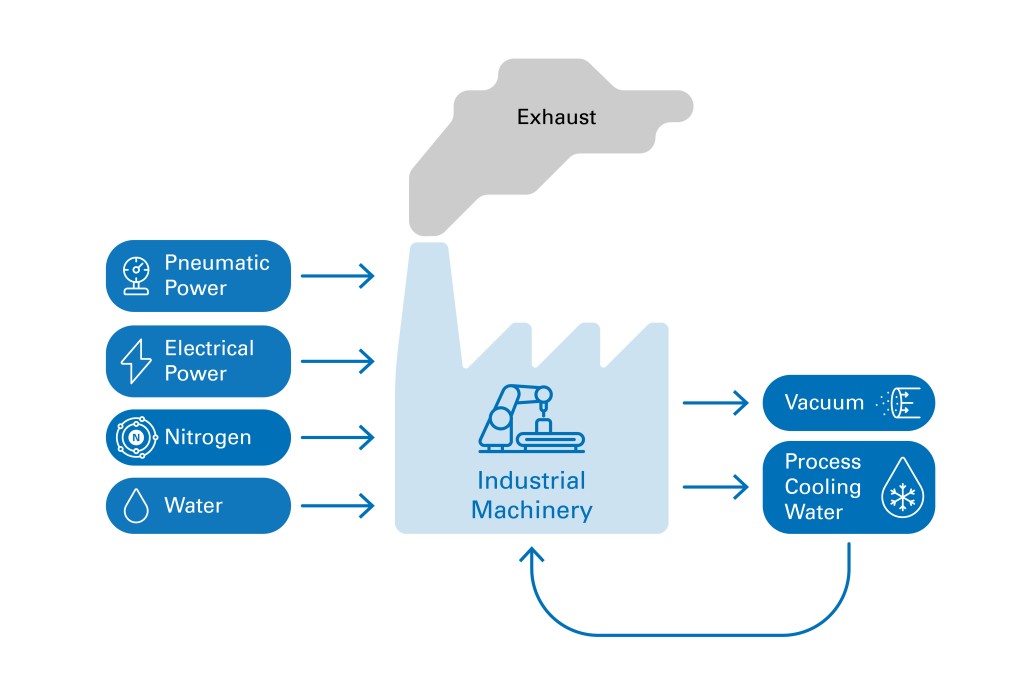

TÜV Rheinland can support you in measuring the energy consumption of your machines. Since consumption does not only consist of electrical energy, our experts will measure and evaluate all other relevant aspects for you:

- Electrical power

- Pneumatic power

- Process cooling water

- Provision of vacuum

- Supply of water and nitrogen

- Energy consumption due to exhaust air

In the evaluation, we list all these energy aspects. If a factor does not apply to your machine, it is rated as zero.

But how do the different energies become comparable? The answer lies in a calculation method introduced by experts from the semiconductor industry (see SEMI standard S23). With this method, the listed energy values can be related to electrical energy using conversion factors. Consequently, the energy contributions can ultimately be compared and added.

Moreover, our experts use a model that makes the operating times of industrial machines comparable. Prior to the evaluation, the operating, standby and pause modes are defined to then be included in the consumption evaluation.

The result is an annual energy consumption figure. Until now, the figure has only been used in the semiconductor industry and is not yet common in other sectors. However, it can also be transferred to industrial machines in further sectors. For maximum transparency in terms of energy consumption, we can support you with reliable calculations.

Customized Solutions for More Machine Safety

We offer you a testing portfolio customized to your company and your machinery, including services such as:

- Safety testing based on German, European and global standards and regulations

- Testing according to the specifications of the international SEMI association: SEMI S2 (general safety), SEMI S8 (ergonomics), SEMI S23 (sustainability) and SEMI F47 (voltage sag immunity)

- Testing of ergonomics, ease of use and service

- On-site or laboratory electromagnetic compatibility (EMC) testing

- Testing of the functional safety of your machine control system

- Safety assessments during commissioning of machines and assessment of consumption figures

- Support in the preparation of risk analyses and risk assessments as well as hazard assessments

- Support with interim tests for new products and product modifications

- Quality assurance during construction (e.g., review of construction drawings and circuit diagrams or quality control of the production before shipment)

- (In-house) training

Market Access Services and Machinery Testing for International Markets

Global trade has enormous growth potential for companies. This means that markets outside the European Union are becoming increasingly attractive. However, international markets have specific demands on products and companies and require different documents and certificates for the approval of machinery.

Thanks to our extensive experience in this field, we keep an overview, manage the process for you and support you in word and deed. As a globally recognized and authorized testing body (NoBo, NRTL, CB, etc.) for impartial approvals, we support you in firmly establishing yourself in the industry. Your needs are important to us. Thus, our experts pay close attention to the unique requirements of your specific situation. We will prepare your quotation while considering your target markets as well as the applicable regulations.

Export of Used Machinery to India: Chartered Engineer Certificate (CEC)

A growing demand for used machinery in India offers attractive export opportunities for companies worldwide. The purchase of used machinery enables Indian companies to acquire high-quality equipment at affordable prices and expand their production capacities. This plays a particularly important role in a dynamic economy like India, as investments in new machinery are often costly. However, the export of used machinery entails regulatory requirements for machine manufacturers that must be met.

To ensure that your machinery reaches India safely and without delay, it is crucial to provide the required certificates and documents. The Chartered Engineer Certificate (CEC) in particular is essential here to facilitate customs clearance and provide legally secure proof of the value of the machinery.

The legal basis for this is Publication No. 25/2015 issued by the Indian Ministry of Finance in October 2015, which stipulates that the value of used machinery must be determined by an authorised inspection service provider. Without a valid CEC certificate, there may be rejections or delays in customs clearance by the Indian authorities, which can result in significant delivery delays and additional costs.

Your Benefits with TÜV Rheinland

With decades of experience in machinery inspection and a global network of experts, TÜV Rheinland is your reliable partner for obtaining CEC certificates. We assist you in meeting Indian regulatory requirements and ensuring the smooth export of your machinery.

Issuance of a CEC Certificate

To obtain a CEC certificate, our accredited CEC engineers conduct a thorough physical inspection of the used machinery or spare parts/components. Various factors critical to the valuation of the machinery are examined.

The following aspects are relevant for issuing a CEC certificate:

- Determining the current value of the machinery/parts in their present condition

- Checking the functionality of the machinery/parts

- Estimating the remaining useful life

- Verifying the year of manufacture, brand, model, and original purchase price

- Classifying whether the items are capital goods, spare parts, accessories, components, or scrap

- Ensuring that the items contain no explosive or radioactive contaminated materials

Rely on our expertise and comprehensive inspection services to bring your machinery quickly and safely to the Indian market. Simply speak to us!

Extensive Operational Security is no Longer Possible Without Cyber Security

Technical systems that are particularly hazardous when it comes to steam, pressure, falling, fire or explosion must already be inspected regularly. In the future, they will also have to be tested for cyber security as well as functional safety. Find out which legal changes are expected.

Your Valued Partner

When testing your industrial machinery, we emphasize the importance of a smooth process. As a "Notified Body", accredited testing laboratory, inspection body and recognized certification body, we are a reliable partner for testing your machinery. Of course, we also offer our experience and expertise for on-site testing at your facility.

For your convenience, we have optimized the process and reduced it to just two simple steps. First, we prepare a quotation based on the documentation you provide about machinery and target markets. In the second step, we perform all the required tests and issue either a certification (positive assessment) or a comprehensive report detailing any open issues, based on which the necessary modifications can be made (negative assessment).

Regardless, our experts are available to answer questions at any point during the testing phase. Contact us if you are interested in an initial review of a similar machine, or in reviews of circuit diagrams or other documents.

Make an appointment with our experts now! Together we will find the right services for you.

Contact