Failure Investigation

Support when failures occur

Despite regular maintenance and inspection of industrial plants, failures can still occur in exceptional cases. The reasons for a failure can vary (for example they can be due to material defect, corrosion, manufacturer fault or assembly error) and are often not easy to detect.

If a failure occurs on a pressure equipment component, this can have serious consequences and can lead to risk to human life, collapse or damage to the fabric building, contamination of the environment or financial losses due to long production downtimes.

Our skilled expert team supports operators in these critical situations by assessing the failure extent and identifying the root cause so that you can develop individual repair and replace strategies. As part of a holistic failure investigation, we also assist you in clarifying liability issues in arbitration proceedings.

Key challenges in dealing with failures

In the aftermath of a failure, owners and operators of assets can find that multiple challenges appear simultaneously, and that incidents can quickly become overwhelming. The following key challenges may arise depending on the individual case:

Difficult to estimate the damage scope and the consequences of the incident, resulting in uncertainties about how to manage the critical situation.

In the event of liability, high compensation payments may be demanded.

Uncertainty about who to trust in critical situations and fear that internal information could become public and severely damage reputation.

Overall anxiety of the consequences due to a loss of control.

Handling multiple different stakeholders in a non-transparent critical situation is difficult. In addition, knowing how to select and apply the right failure assessment method(s) requires specialist expert input.

With our broad failure investigation service portfolio we are able to support you in critical situations in order to overcome these challenges and help you to get the incident under control.

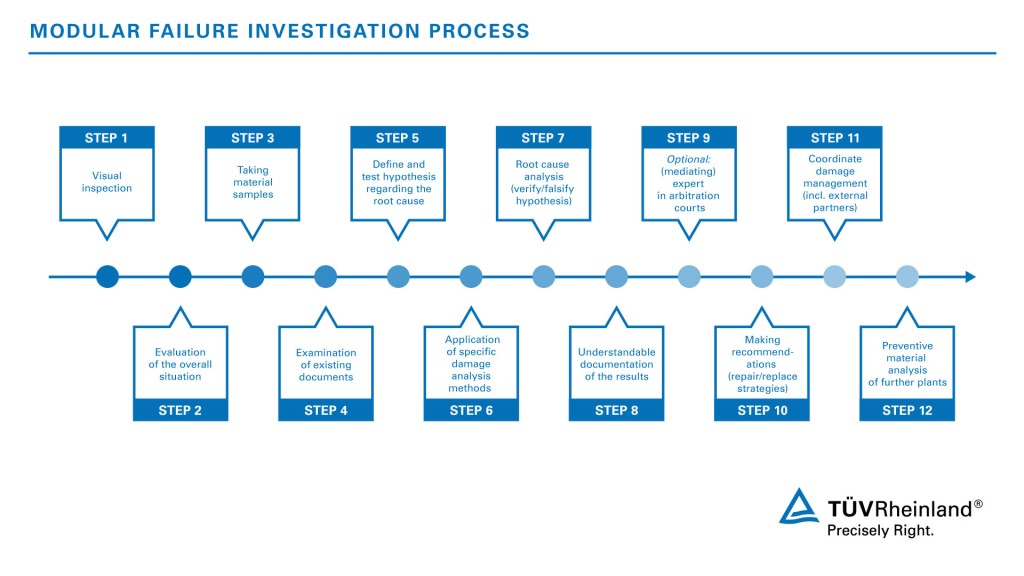

Modular failure investigation from start to finish

Our expert team supports you in the event of failures almost anywhere in the world (for example South America, Germany, China). Depending on your needs, our inspectors can provide:

- single failure investigation services (like identifying the root cause); or

- coordinate the whole failure management process from start to finish.

The key steps of our whole failure management process are illustrated below:

When engaging us for the whole failure management process, you benefit not only from the root cause analysis, we also coordinate the damage management and make recommendations with regard to your individual repair and replacement strategies. Additionally, we support you as an independent expert in arbitration proceedings in order to clarify liability issues.

Identifying the failure root cause as part of the investigation process

In critical situations, root cause analysis takes a crucial role. Our experts at TÜV Rheinland have extensive experience in the selection and application of different advanced testing methods used for failure analysis.

Based on a sample examination by the following mechanical, fractographic, metallographic and spectral-analytical methods our experts can recommend suitable action items:

Benefit from our failure investigation services

- Rapid support: Get rapid help in critical situations where you may not know what to do

- Failure assessment: Identify the root cause and assess the scope of the failure

- Clarification of liability issues: Prevent possible compensation payments

- Experienced team: Receive support from our experts with knowledge of the latest inspections methods and relevant regulations

- Recommendations: Solve the problem based on our targeted recommendations regarding your repair and replacement strategies

- Damage limitation: Minimize reputational damage and financial losses (for example by reducing plant downtimes)

- Independent partner: Benefit from our role as an independent third party inspector with the ability to conduct objective evaluations and raise appropriate recommendations

Contact

/tuv-rheinland-finite-element-method-fem_core_4_3.jpg)

-services/tuv-rheinland-ultrasonic-testing-services_core_4_3.jpg)