Nuclear facilities are capital-intensive projects with significant time requirements for licensing, development, and construction. These requirements take place against the background of a strict regulatory environment, where in some countries the relevant oversight or licensing body actively monitors the build and installation of plants and is authorized to exert real influence over the process.

The interdependencies between various project activities in the nuclear sector are often underestimated. To minimize long lead times, manufacturing of plant components often begins before the plant design is completed. This is risky, since any changes in design have an impact on downstream construction phases and the relevant supply chain.

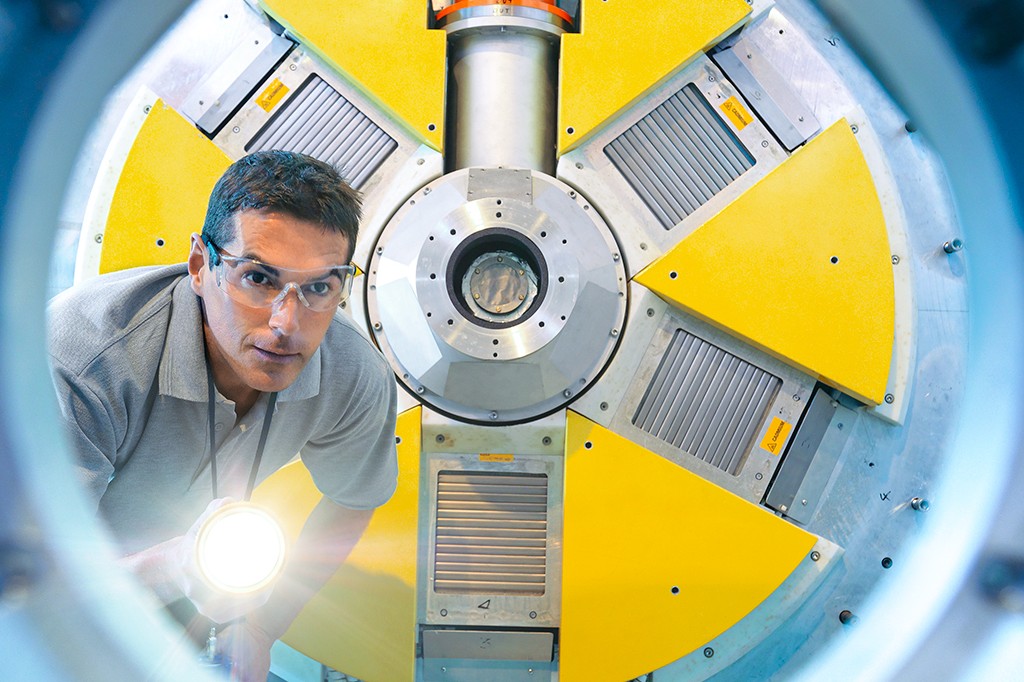

During the manufacturing and construction phase, it is also critical to select the correct components and materials in order to achieve the required safety and quality standards, and to employ well-trained and experienced workers. Failing to sufficiently address all these aspects runs the risk of long interruptions, delays, and/or rising, unpredictable costs and potential safety issues.

Equipment qualification and supplier management – two pillars of success for building a nuclear plant.

The components and materials chosen play a fundamental role in ensuring the safety of a nuclear plant. Relevant national and international standards must be considered when selecting equipment. This requires a solid understanding of the local regulatory environment – both for the countries of origin (where the components were manufactured) and the destination (where the components will be installed). Almost every country has different standards that must be met by the plant designers, builders, operators, etc.

Besides the quality of the materials, choosing the correct supplier is critical, striking the balance between cost and quality in order to meet the strict safety regulations governing nuclear equipment. Supply chains are becoming increasingly global and more complex, which calls for well-organized and strategic supplier management in order to ensure an acceptable quality/cost balance is met.

As a partner of the Equipment Qualification Service Alliance (EQSA), we and our partners are here to help you qualify nuclear components, irrespective of which country they originate from or will be used in.

Delivering an adequate equipment design through verification and validation.

Development of the design of the various systems which make up a nuclear plant is a significant task which involves numerous stakeholders, including the applicable regulatory body in some countries. Fundamental to the design process is ensuring that the end product meets the required functional, quality and safety standards. This can be achieved through application of an appropriate development lifecycle, managing design development from concept through to site acceptance. We have extensive experience in supporting all lifecycle phases, including:

- Optioneering

- Design requirement capture (both functional and technical)

- Technical support to design development

- Design justification

- Safety case production

- Installation and commissioning planning

- Testing and commissioning

- Project Management and stakeholder management

Our consultants deliver this support across all engineering disciplines, as well as specialist services such as Human Factors and Security.

Our services for the successful construction of a nuclear plant.

The construction and build phase forms the basis for economically sustainable and successful plant operations. That is why it is important to work with an experienced, expert partner like us – so you benefit from the necessary regulatory know-how and can make the right decisions when it comes to suppliers and materials. We support you with a range of services:

- Supplier qualification, including training

- Supply chain oversight, including inspections and audits

- Type approvals

- Hardware, software, and system tests

- Environmental laboratory testing

- Software qualification

- Supervision of manufacturing and construction as second or third party (ISO 17020 Type A Inspection Body)

- Equipment qualification (EQSA)

- Design justification

- Safety case production

- Physical and cyber security

- ISO 19443 Certification for the Nuclear Industry

As an international testing and inspection provider, and nuclear safety consultancy with a broad portfolio of services, we provide you with a service package tailored to your specific needs. In addition to the key services essential to nuclear plants, you also benefit from our expertise in related areas, like industrial supply chain inspections and cybersecurity services for comprehensive nuclear safety.

Training in the area of design and construction of a nuclear facility.

Skilled professionals are in high demand, especially for the construction of new plants. Therefore, we offer various training for this sector. Choose from our training the one that suits you best:

- Engineered Risk Control Systems and Performance

- Implementation of a Regulatory Regime

- Nuclear Lifecycle Hazards and Risks

- Nuclear Reactor Basics

- Nuclear Reactor Safety Principles

- Principles of Regulatory Systems

You are interested in further nuclear training? Have a look at our Training and Education Area. You will find there all trainings along the entire life cycle of a nuclear facility.

Further Services