Moving forward safely and reliably: Comprehensive testing to verify the conformity and durability of your products

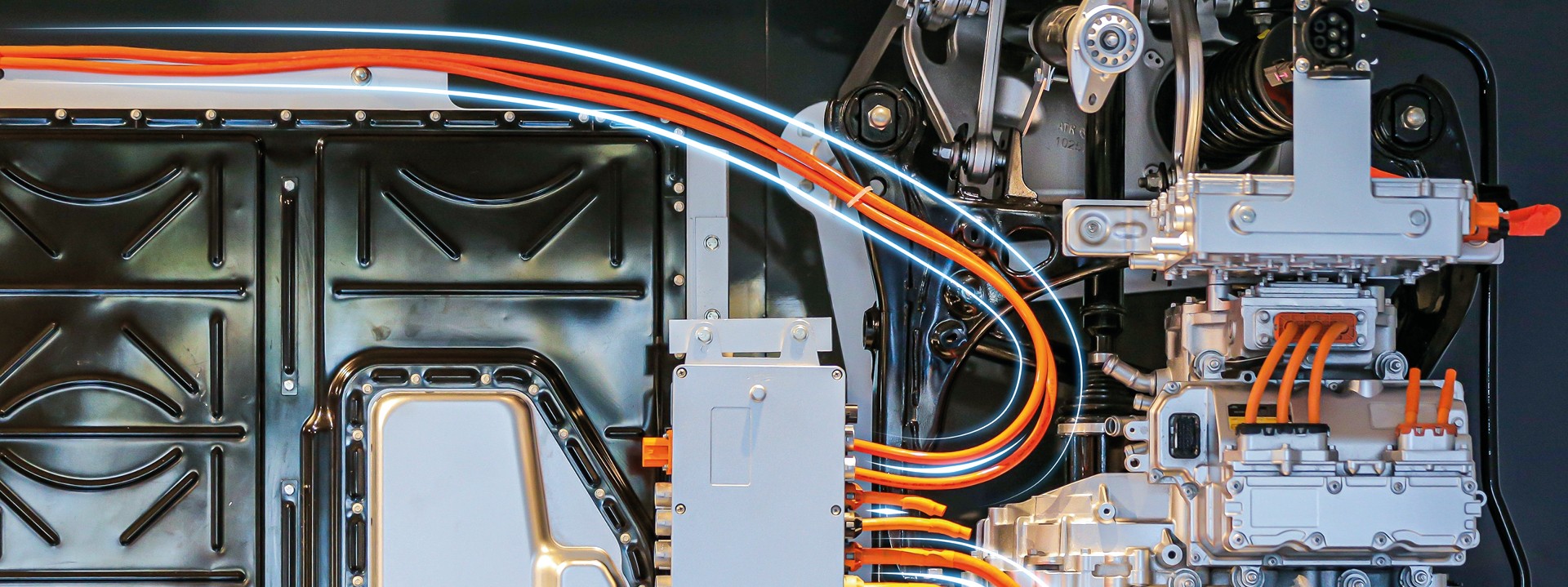

Electrified drives usually contain fewer mechanical components than traditional thermal powertrains. At the same time, they require many components with complex electrical and electronic systems. These must all have maximum reliability and durability. That is what manufacturers and users alike expect from electromobility. This is all the more relevant as electric drives are increasingly finding their way into commercial vehicles, agricultural machinery, rail technology, maritime ship technology and aircraft – areas where the failure of individual components before the end of their planned service life must not be allowed to occur.

Our specialized test laboratories test the reliability and durability of your drive components for electromobility. Our state-of-the-art facility in Nuremberg, for example, is equipped to perform all standard test procedures and holds an accreditation as a test laboratory from DAkkS, the German accreditation body. You benefit from our short testing times and our many years of experience, and improve your market position by having your products tested. The safety and reliability of your drives is what drives us.

| Electric motor | E-mobility inverters |

| Electric drives | Hybrid transmissions |

| Drive concepts | Powertrain components |

| Power electronics | Circuit electronics |

Life cycle testing under realistic conditions with all loads and stresses

Our compatibility and quality tests expose your electromobility drive components to all the stresses they must withstand in their real-life cycle. This is done at such short intervals and with so little lead time that you can significantly accelerate your development cycles and meet your customers' schedules.

Our test laboratory in Nuremberg offers a wide range of redundant testing facilities including four “shakers” alone that simulate high mechanical loads. This means that even when demand is high, our testing capacities are available to you at short notice.

Upon request, we also carry out the so-called Highly Accelerated Lifetime Test (HALT). With this test, we not only test a product under real-life conditions for a specified period, but until a weakness becomes apparent. The HALT test provides you with additional data on the durability of your e-drive components.

Take advantage of our expertise and get all necessary verifications of the reliability and durability of your products from one single source.

Contact us about the testing of electrical and electronic drive components.