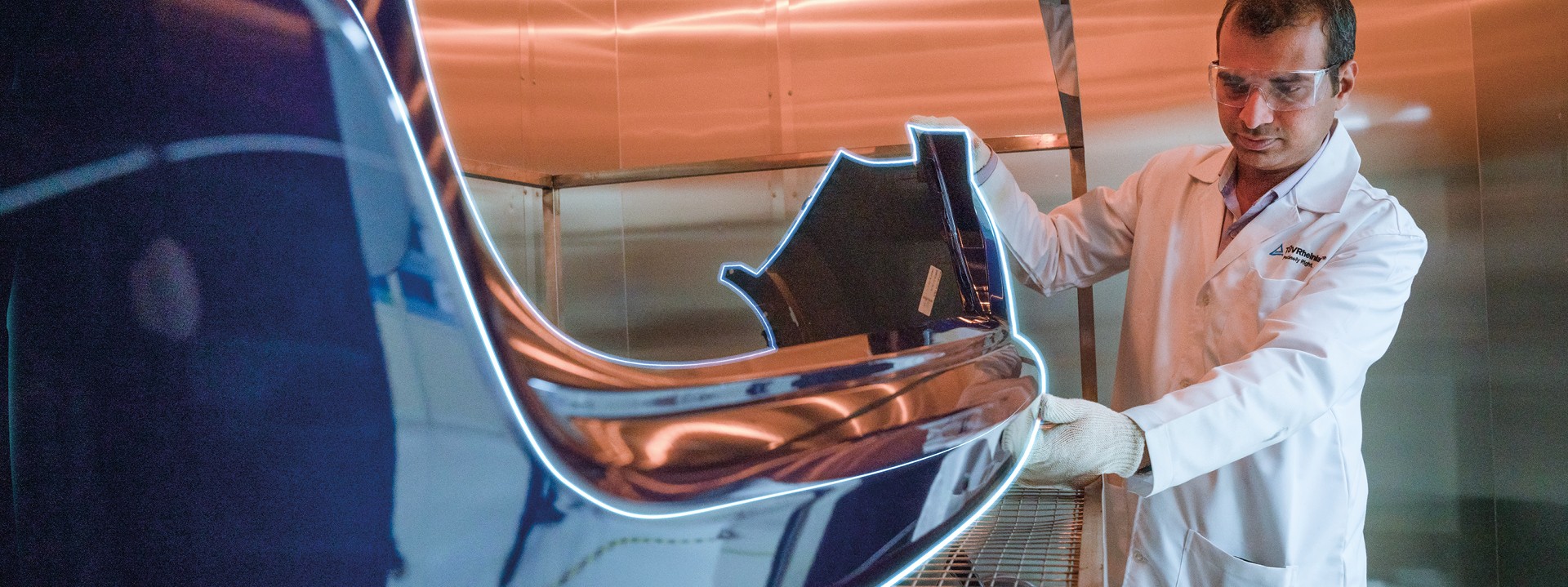

Safe and reliable even under extreme conditions

Electromobility products are exposed to many external stresses. The diversity of electromobility applications alone illustrates the wide range of mechanical requirements. Whether electric cars, commercial vehicles and two-wheelers, industrial trucks, railroad technology, maritime ship technology or electrically powered aircraft – all of them are exposed to temperature fluctuations, moisture, dust, strong vibrations, salt exposure, mechanical shocks and more. And none of these stress factors is allowed to have an impact on the performance. Can your electrical and electronic products withstand these kinds of stresses?

We help to ensure the safety of electrical components in the areas of development, qualification and quality assurance, as well as through regular functional tests. Our laboratory for environmental simulation conducts tests in accordance with many relevant standards, whether IEC/EN 60068, ISO 16750, EN 61373, DIN EN 50155, ISO 20653, DIN EN ISO 9227 etc. or customer-specific requirements by manufacturers or OEMs.

Our test laboratory is DIN EN ISO/IEC 17025 accredited. This means that the test protocols and reports prepared by us are widely accepted. With our independent tests, you document the product requirements of your electrical products against manufacturer or standard requirements.

In addition to our superior technical expertise, you benefit from our short distances for the complete range of testing. This allows you to quickly eliminate any identified sources of error. Furthermore, the teams in our laboratories are very flexible in responding to individual customer requests.

| Vibration tests with or without temperature / climate superposition (sine, multi-sine, noise, sine and noise, resonance tests) | Mechanical shock tests |

| Drop tests | Climate and temperature tests |

| Thermal shock tests / air to air / medium to medium | Corrosion tests |

| Corrosion change tests | Media resistance tests |

| Transportation tests | IP protection classes testing |

| IK protection classes testing | Splash water and ice water shock tests |

| Pressure pulsation tests | Harmful gas, single gas or mixed gas testing |

| Electrical tests | Complete qualification tests including project management |

| High Accelerated Life Test (HALT) and High Accelerated Stress Screening (HASS) Test | |

| Our experts will be happy to answer your questions and provide further information on environmental simulations. | |

Contact us about the testing of electromobility components.