In order to confirm that test samples work under irregular conditions and in abnormal environments, the battery testing facility is equipped with state-of-the-art test equipment ensuring highest safety standards. With the test chambers installed, we aim to support battery energy technologies in a fast developing industry. Testing services are offered for a wide variety of products, ranging from batteries used in electric and hybrid electric vehicles, industrial / household stationary energy storage systems and portable applications.

Why TÜV Rheinland (KTAC)?

Safety of KTAC insured by our abuse chambers

State-of-the-art facility

ISO 17025/ KBA/ SII Accreditation

Technical service offered at own laboratory

Wide range of services (please refer to the following list)

Expertise in national and international regulations and standards (participation of working groups under UN, WP29)

Largest laboratory which is designated only to ESS (Energy Storage System) in Japan

- Major OEM & TIER I companies are our customers

- Offering flexible and creative service to meet your needs ( design, development and implementation of customized testing systems)

| Mechanical Tests | Vibration, Impact, Penetration, Crush, Drop, Free-fall test |

| Electrical Tests | Internal short circuit, external short circuit, overcharge, forced discharge test |

| Environmental Tests | Immersion: LLC, Salt Water, Temp. & Humidity cycle, Heat shock, Altitude test, Thermal stability, Thermal abuse test using Calorimeter |

| Other Services | X-ray/CT scanning service, Gas Chromatography, Stone Chipping |

Major standards we handle

- Legal regulation: Electrical Appliance and Material Safety Law (DENAN Act)

- Related standard: JIS C 8712, JIS C 8713, JIS C 8714, etc

- UN38.3 (Recommendations on the transport of dangerous goods - UNECE)

- R100.02 (Safety regulation of REESS for electric power train)

- *KBA Accreditation (Federal Motor Transport Authority in Germany)

- SBA S1101 (Subsidy for stationary rechargeable energy storage system)

- Others (e.g.):

- CB report can be issued upon following IEC standards.

- IEC61959, IEC61960, IEC62133, IEC62281, IEC62660-1, IEC62660-2, IEC60086-4

- UL1642, UL2054, UL Subject 2580, SAE J2464, FreedomCAR

- BATSO 02

For more details, please send us your inquiry from the "Contact" button.

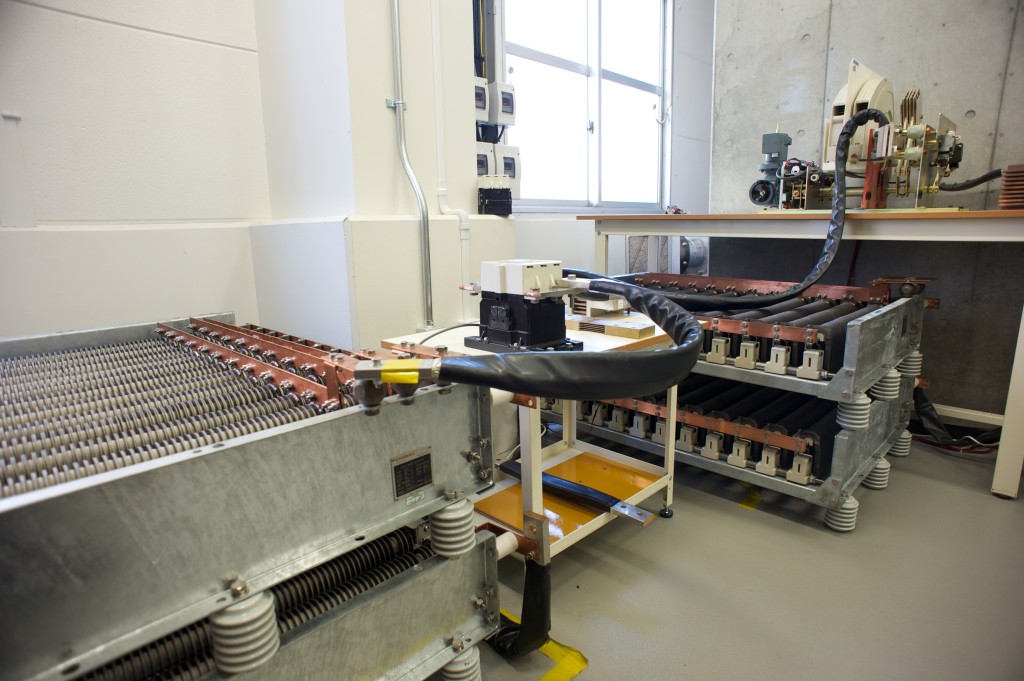

Testing Equipment in KTAC

Battery testing facility in KTAC is equipped with state-of-the-art test equipment ensuring highest safety standards.

For pictures and the details, please refer to Testing Equipment.

Abuse Test Chamber

Destructive Test Areas for battery

CO, H2, 3IR and Temperature Sensor

Filter (Scrubber) System for emitted gas

Inner size: W 4000 x D 4000 x H 3500mm - 1 Chambers

Inner size: W 4000 x D 4000 x H 3000mm - 3 Chambers

- Automatic Argonite Fire Extinguisher System and safety structure which can withstand explosions of large batteries.

- Created gas during test will be released after cleaned up through dry and wet scrubber

Vibration System

Frequency:5~2000Hz

Rated Force:60kN

Max Velocity:1.8m/s

Max displacement:63.5 mmp-p

Table size at Horizontal:W 900 × D 900mm

Table size at Vertical: W 700 × D 700mm

- Shock test available

Example of test standard:

ISO 12405-1

IEC 62133

IEC 62660-2

JIS C 8712

JIS C 8713

UN3480 – 38.3 T3

UL1642

QC/T 743

PSE

Free-Fall Shock Tester

Max Acceleration:1000G

Max sample mass:181kg

Table size:W 610 × D 610mm

Example of test standard:

ISO 12405-1

IEC 62133

JIS C 8714

JIS C 8712

JIS C 8713

Overcharge / Force Discharge Tester

Max current: 800A

Max voltage: 500V

Ambient temperature during test: normal temperature ~57℃

Inner size of test box:

W 1300 x D 1130 x H 906mm

- Special test out of above condition can be performed.

Example of test standard:

ISO 12405-1

IEC 62133

IEC62660-2

JIS C 8712

JIS C 8715-2

SBA S 1101

UN3480 - 38.3 T7

UN3480 – 38.3 T8

UL1642

QC/T 743

PSE

Crush Tester / Penetration Tester

Max Force: 250 kN

Speed: 0.1~10mm/sec

Ambient temperature during test:normal temperature~50℃

Inner size of test box: W 600 x D 600 x H 680mm

- Compliant with a various standard replacing jigs.

Example of test standard:

ISO 12405-1

IEC 62133

IEC62660-2

JIS C 8712

JIS C 8713

JIS C 8714

UN 3480 – 38.3 T6

UL 1642

QC/T 743

SAND 2005-3123

SAE J 2464

PSE

External Short Circuit Sytem

External resistance: 0.5mΩ~100mΩ

Test capability: 12500A / 32sec

Ambient temperature during test: normal temperature~57℃

Inner size of test box:

Maximum:W 1300 x D 1130 x H 906mm

Example of test standard:

ISO 12405-1

IEC 62133

IEC62660-2

JIS C 8712

JIS C 8714

JIS C 8715-2

SBA S 1101

UN3480 – 38.3 T5

UL1642

QC/T 743

Performance Test System

For cell: 5V/980A (Max)

For module: 100V/600A (Max)

- More than 100 channels available

Example of test standard:

ISO 12405-1

IEC 62660-1

JIS C 8711

QC/T 743

JIS C 8715-1

UN3480 – 38.3

Temperature Chamber

Temperature: -40℃~100℃

Inner size: W 1000 x D800 x H 1000mm

W 700 x D 700 x H 950mm

W 600 x D 800 x H 850mm

Example of test standard:

ISO 12405-1

IEC 62660-1

JIS C 8711

QC/T 743

JIS C 8715-1

UN3480 – 38.3

Temperature and Humidity Chamber

Temperature: -40℃~100℃

Humidity: 20~98%RH

Inner size: W 600 x D 500 x H 600mm

Example of test standard:

ISO 12405-1

ESPEC Chamber

Temperature:-40℃~180℃

Humidity:98%(MAX)

Inner size:W1100 x D1000 x H1000mm

Weiss Chamber

Temperature:-65℃~120℃

Humidity:95%(MAX)

内寸:W3700 x D3200 x H2500mm

Door size:W2000 x H2500mm

Thermal Cycle Chamber

Temperature: -40℃~100℃

Rapid Temperature Change: Between -40℃ to 80℃ within 30 minutes

Max sample mass: 100kg

Inner size: W 1000 x D 800 x H 1000mm

Example of test standard:

ISO 12405-1

IEC 62133

IEC 62660-2

JIS C 8712

JIS C 8715-2

UN3480 – 38.3 T2

UL 1642

UL 1973

SAE J 2464

SBA S 1101

Heat Shock Chamber

Hot temperature: 60℃~200℃

Cold temperature: -65℃~0℃

Inner size: W 650 x D 400 x H 500 mm

Example of test standard:

IEC 62133

IEC 62660-2

JIS C 8712

JIS C 8714

JIS C 8715-2

SBA S 1101

UL1642

C/T 743

Altitude Simulation Chamber

Temperature: 10~80℃

Air pressure: 101.3~10.1kPa

Inner size: W 800 x D 700 x H 800mm

Example of test standard:

IEC 62133

JIS C8712

UN3480-38.3 T1

UL 1642

PSE

PEC Performance system (for Cell―Type SBT0550)

battery performance test system (PEC for cell Type)

5V/50A 24ch (max 600A 2ch possible)

charge/discharge system (PEC for cell Type ACT0550)

5V/50A 40ch (max 2000A 1ch possible)

reduce testing time by chamber temperature control, automatically control each cell SOC

Characteristic test based on practical amount of each cell

High accuracy

- control current / voltage by ±0.03% (full scale)

- rise rate of current 1msec (no over shoot)

- sampling 1msec

Gas Analysis system (Pressure Vessel + GC/Agilent Tec-made (7820A))

Fraunhofer ICT-made

Max pressure: 30bar

Inner size: Φ508mm (150L)

Test item: Overcharge, Forced discharge, External short circuit(max.900A)

Measurable gas: H2/CO/CO2/Others

Sampling method: Sampling bags, max 8 times in 1 test

DC load

High voltage high capacity DC electric load system (NHR-4760-24)

600V/1200A/24kW

For high voltage battery pack discharge, capacity check

For lead-acid battery cranking test by high current

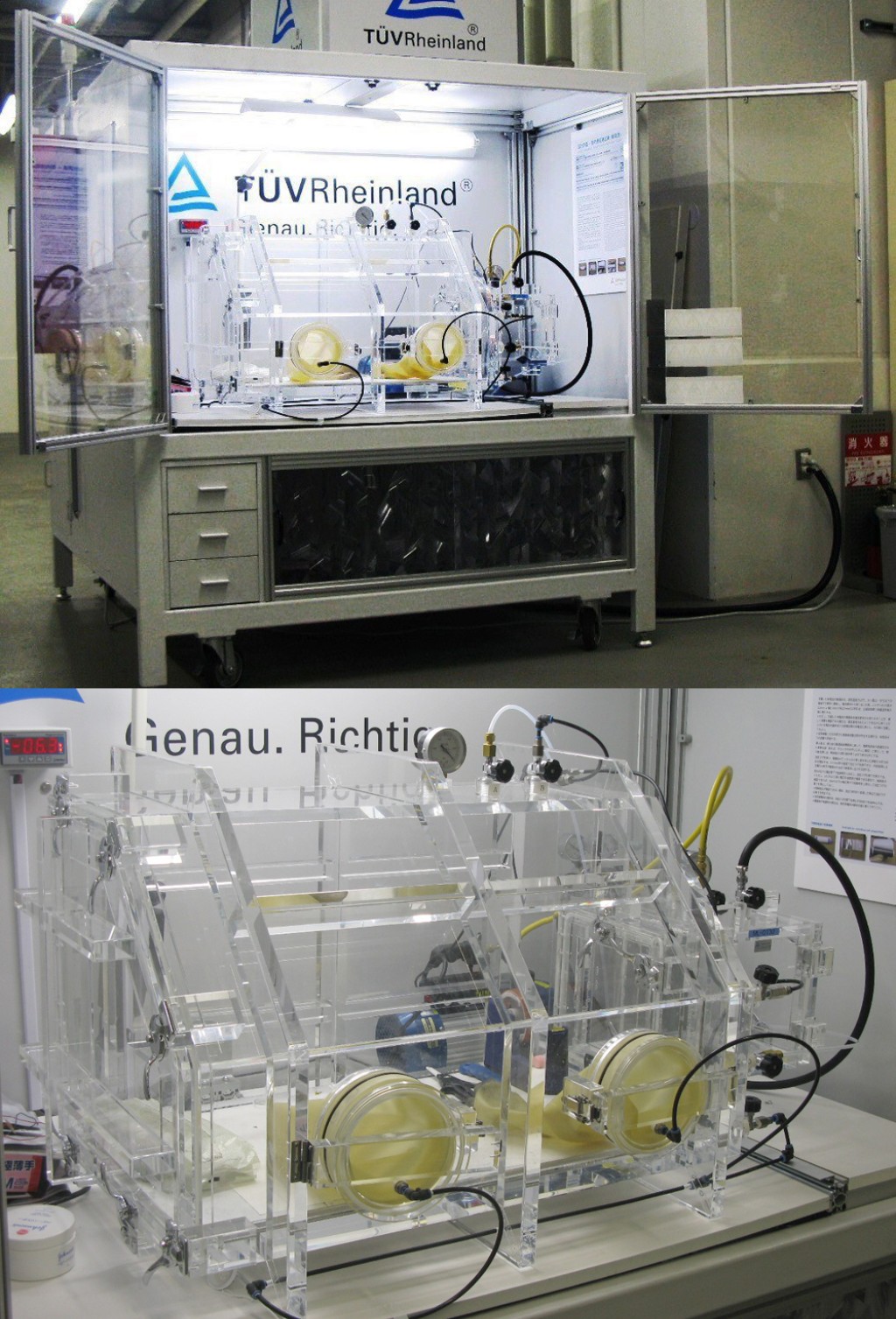

Forced Internal Short Ciruit test

This test assumed that a conductive foreign matter is mixed into the battery.

Simulating such situation by mixing L-shape small Nickel piece into disassembled battery.

Then crush a battery until internal short circuit occur.

Disassemble a battery in a glove box purged with argon gas and put nickel piece into a battery.

Example of test standard: JIS C8714, JIS C8715-2

IMV vibration machine + Temperature/Humidity chamber

Vibration machine:

Frequency: 5~3000Hz

Rated Force: 16kN

Max Velocity: 2.2m/s

Max displacement: 51 mm p-p

Table size at Horizontal: W 630 × D 630 mm

Table size at Vertical: W 500 × D 500 mm

Temperature/Humidity Chamber:

Size: W 1000 x D 1000 x H 1000

Temperature Range: -40 ~ +150 ℃

Humidity Range: 20%~95% RH

Temperature change rate:-40 ~ +150 ℃ = within 190min (for cooling and heating, not linear gradient)