Overview

At TÜV Rheinland, we bring a wealth of expertise to the forefront of SEM-EDX Testing, utilizing cutting-edge Scanning Electron Microscopy techniques to delve deep into the intricacies of materials. Our services extend across various industries, providing valuable insights into external morphology, chemical composition, and crystalline structure. Accredited under NABL ISO/IEC 17025, our experts bring specialized knowledge and extensive experience to every analysis.

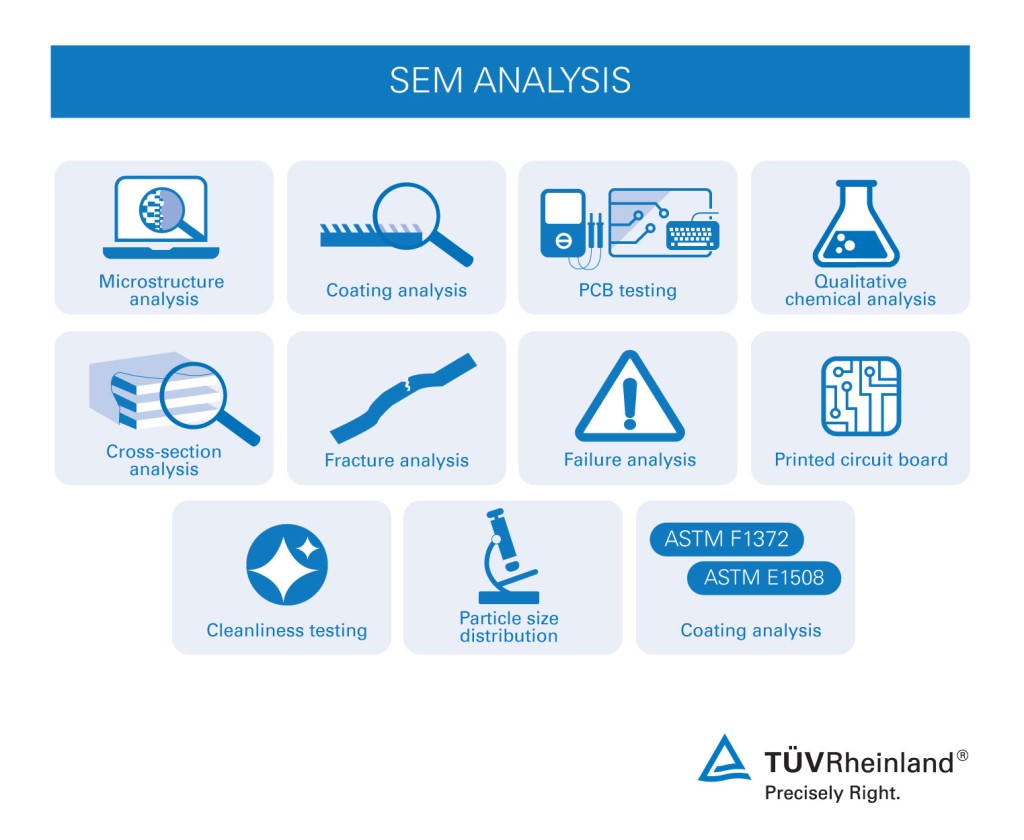

SEM Analysis:

Our Services:

- Manufacturing

Quality Control:

- Material Verification: Ensure components meet specified standards through SEM-EDS material composition verification.

- Contaminant Identification: Identify and quantify contaminants, ensuring manufacturing inputs' purity.

Failure Analysis:

- Root Cause Analysis: Investigate component failures, understanding the elemental composition at the microscale.

Coating Evaluation:

- Coating Thickness and Composition: Evaluate coating thickness and elemental composition, ensuring adherence to specifications. - Research and Development (R&D):

Material Research:

- Nanostructure Analysis: Support the development of advanced materials with specific properties through SEM-EDS.

- Alloy Development: Contribute to metallurgical R&D by analyzing alloy composition and microstructure.

Device Development:

- Semiconductor Analysis: Analyze elemental composition during semiconductor development and research. - Automotive Industry:

Engine Component Analysis:

- Metallurgical Analysis: Optimize engine component performance and durability through microstructural analysis. - Railways:

Track and Wheel Inspection:

- Wear Analysis: Optimize maintenance schedules and improve component longevity through wear pattern analysis. - Aerospace Industry:

Composite Materials Analysis:

- Composite Structure Inspection: Inspect and analyze elemental composition for strength, durability, and defect identification.

- Corrosion Analysis: Investigate corrosion patterns in aerospace materials exposed to harsh environments. - PCB Manufacturing:

Quality Control:

- Solder Joint Inspection: Examine solder joints on PCBs, ensuring proper composition and quality.

- Analysis of Electronic Components: Verify authenticity and quality through elemental composition analysis.

Applications:

Our SEM-EDS services cover a wide range of applications, including identification of metals, particle contamination elimination, product and process failure analysis, surface morphology examination, and much more. From microscopic feature measurement to IC failure analysis, we offer comprehensive solutions tailored to your needs.

Standards:

Adhering to the highest industry standards, our SEM EDX Testing complies with IPC 610A-E, ISO 16232-10, ASTM E1508, ASTM F1372, and ISO 1463. Our tests and documentation are customizable to meet your specific organizational requirements.

At TÜV Rheinland, we look forward to the opportunity to serve you with excellence, providing unparalleled insights that drive the success of your projects and products.

Contact